Contact: Mr. Yang, 13925789871

Mr. Hu, 13509020493

Tel: 0769-82600378

Mailbox: imdiml@163.com

Company website: www.dglichao.cn

Address: No. 4, Hongye Middle Road, Yongtou, Chang'an Town, Dongguan, Guangdong, China

website:en.dglichao.cn

Contact: Mr. Yang, 13925789871

Mr. Hu, 13509020493

Tel: 0769-82600378

Mailbox: imdiml@163.com

Company website: www.dglichao.cn

Address: No. 4, Hongye Middle Road, Yongtou, Chang'an Town, Dongguan, Guangdong, China

website:en.dglichao.cn

The hot sale of OPPO A79 mobile phone indicates that the new IMT process will make plastics regain new color in the mobile phone industry.

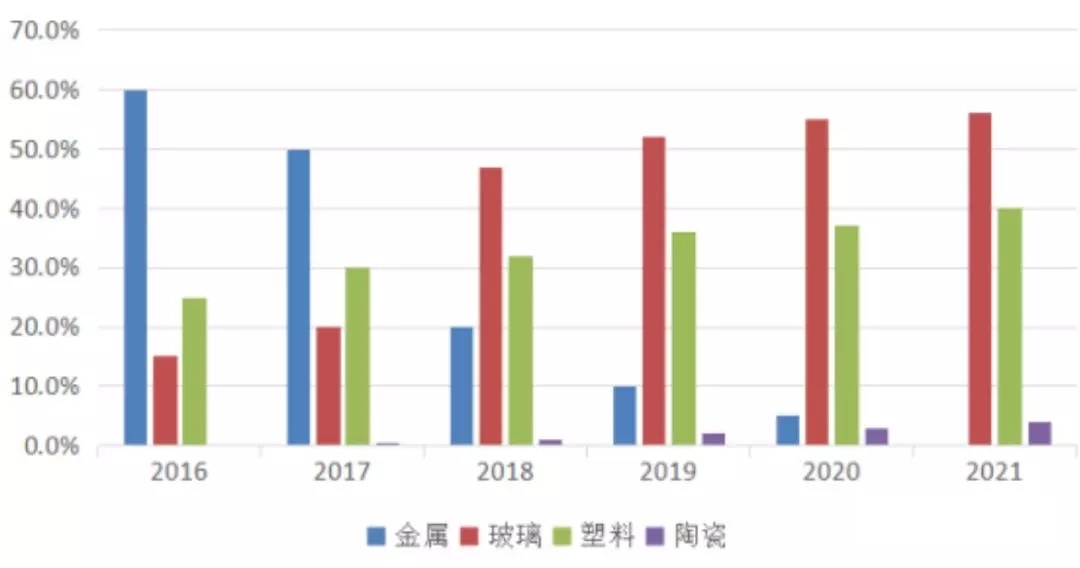

In the 5G era, 3D curved cover plates are increasingly sought after. This has caused a huge change in the selection of mobile phone cover: metal materials have gradually withdrawn from the stage, and non-metallic materials have begun to lead the trend. Among them, glass, ceramics and plastics stand in three parts. Glass and ceramics occupy the mid-to-high-end consumer market, while plastics are widely found in the low-end consumer market and a small part in the mid-end consumer market.

Figure Changes and predictions of mobile phone back cover materials in recent years

The hot sale of OPPO A79 mobile phone indicates that plastic is emerging in the mid-end consumer market of mobile phones through the IMT process.

Illustration ice flame blue mobile phone rear view

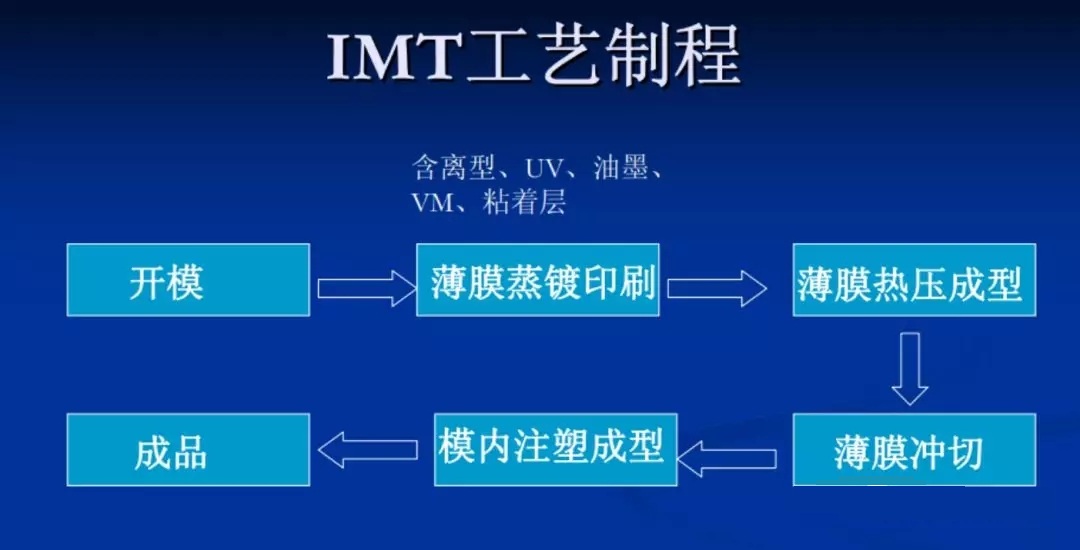

I. Introduction of IMT injection molding process

In-mold injection transfer IMT (Inner Molding Translate label) is a simple understanding and integration of the in-mold insert molding IML (Inner Molding Label) diaphragm production + in-mold transfer injection molding IMR (Inner molding Roller) transfer technology A new process.

Figure IMT process flow diagram - from the network

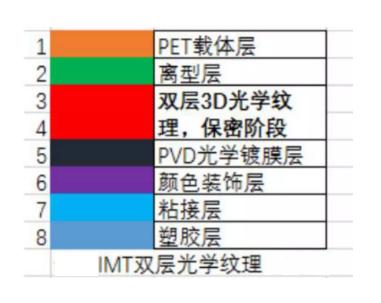

Figure IMT process product structure

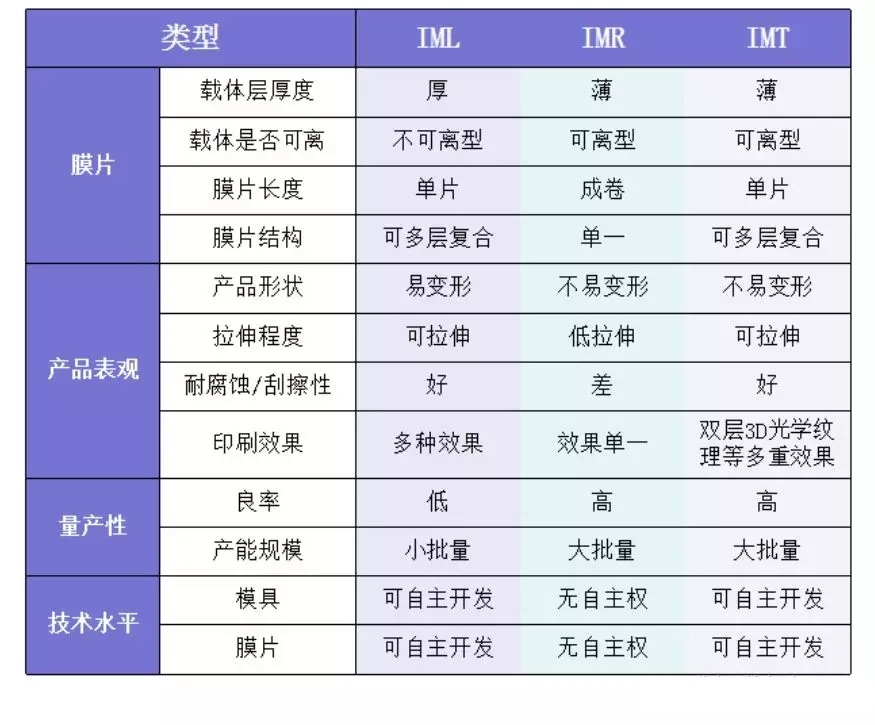

Second, IMT and IMR, IML injection molding process comparison

IMT and IMR, IML belong to the in-mold decoration process IMD. The advantages and disadvantages of the three processes are as follows:

Figure IMT and IMR, IML three in-mold decoration process comparison chart

Third, the advantages and disadvantages of IMT and composite sheet high pressure forming

In the production of 3D curved mobile phone back cover, there is no significant difference in the appearance of the product between the IMT injection molding process and the composite sheet. The main problem is the cost. The difference in cost between them is due to the following two aspects:

Material cost

When manufacturing the back cover of the 3D curved mobile phone, the IMT injection molding process can be completed in one shot, while the composite plate needs to be printed on the whole PVD and texture, and then subjected to hot bending, hardening, CNC and other processes. Achieve the same effect. In the post-manufacturing process of composite sheet metal, there is a problem of safety margin, which leads to waste of materials, and the overall material cost is inevitably higher than the IMT process.

2. The overall structure cost of the mobile phone

The 3D curved mobile phone back cover, like the glass, is a pure decorative part in the product structure of the mobile phone. The overall structural load of the mobile phone is pressed on the middle frame, which inevitably leads to higher requirements for the selection of the middle frame and more structure. complex. The cost of the middle frame is inextricably linked to its structure: for each hole in the structure, there is one more process, and the cost increases.

When using the IMT injection molding process, it can realize the plastic buckle position and take part of the structural function, so that the overall structural cost of the mobile phone is reduced.

Fourth, the progress of IMT's core technology - film and composite hot press forming process

The IMT injection molding process has existed since the 2G era. Why has it been applied to the production of mobile phone back cover in the near future? The trick is the advancement of its diaphragm material process and the production of composite hot press forming processes.

1. Progress in diaphragm material technology

Along with the wave of 5G mobile phones, the deformation and hardness of diaphragm materials are solved. The products meet the requirements of the IMT industry. At the same time, the material double-layer 3D optical texture and the diversity of the effects of the separation optical 3D make the products rich in color. Beautiful, more scientific and stylish.

Figure IMT double layer 3D optical texture diaphragm

2. Production of composite hot press forming process

Unlike conventional PET and PC materials, the physical properties of the composites are different from conventional hot press forming processes. Dongguan Lichao Precision Machinery Co., Ltd., after arduous research and development experiments, finally made the hot press forming of composite materials (PMMA+PC) meet the technical requirements of mass production, and won the reputation of customers.

Figure Composite press back cover after thermoforming (Dongguan Lichao Precision Machinery)

Figure Composite phone back cover hot press forming site (Dongguan Lichao Precision Machinery)

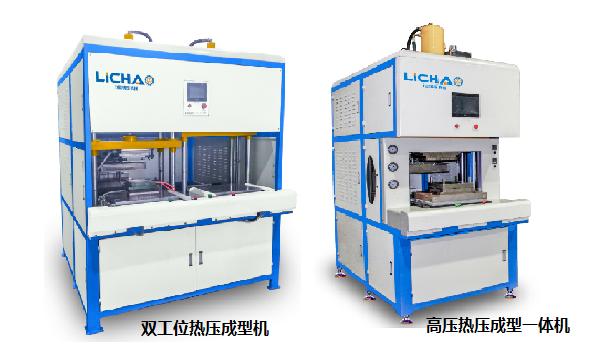

Figure Composite hot press forming machine (Dongguan Lichao Precision Machinery)

Conclusion: With the maturity of the composite hot press forming process and the realization of mass production, it has lifted a major worries of the domestic IMT injection molding process. In the 5G era, I believe that plastics will definitely be heavy in the mobile phone industry. Rejuvenate.